Freeing up resources: Give your team the gift of time with data insights

As a wind or solar PV farm operator, you likely ask yourself day in and day out how to improve energy production and reduce O&M (Operations & Maintenance) cost. Is there any performance improvement potential? How are my assets performing compared to others? Can we improve our operational efficiency without adding costly resources to the mix?

Meanwhile, you have also likely heard of, and may be tired of buzzwords like data science (Machine Learning and Artificial Intelligence) thrown around as the panacea to save the world from climate change while improving your AEP (Annual Energy Production).

In reality, data science is useless without proper domain context. Ninety percent of anomalies identified by the application of data science only on turbine operational data yields something false. Yes, 90 percent!

The good news is that with the help of the right digital partner with domain knowledge, you can start building the DNA and processes, to take advantage of the vast amount of data your assets already generate. They are the building blocks that can unlock insights you didn’t know was possible and provide unprecedented transparency about your assets.

"Our customers get a clear understanding of their turbine operations, and most importantly, can pinpoint areas of improvement when compared with peers."

At Utopus Insights, with the backing of a strong, collaborative parent company, Vestas, we combine our in-depth turbine OEM-specific knowledge, turbine design data, O&M records, and cutting-edge data science technology to provide timely and actionable insights to maximize your wind farm performance. As an example, partial performance loss is often an area overlooked by turbine performance. It is counted as available; however, it does not generate as much as energy as it should be. It also confuses your power curve analysis (that is exactly where data science without domain knowledge fails as an example).

So, here's how we suggest the best approach. First things first: get a clear baseline view of current operations. This is where Utopus Insights provides industry standard methods quantified by measurable KPIs (Key Performance Indicators) such as:

- Time-based asset technical availability

- Time-based operational availability

- Comprehensive loss break down, including power curve loss, partial performance loss, availability, and downtime loss

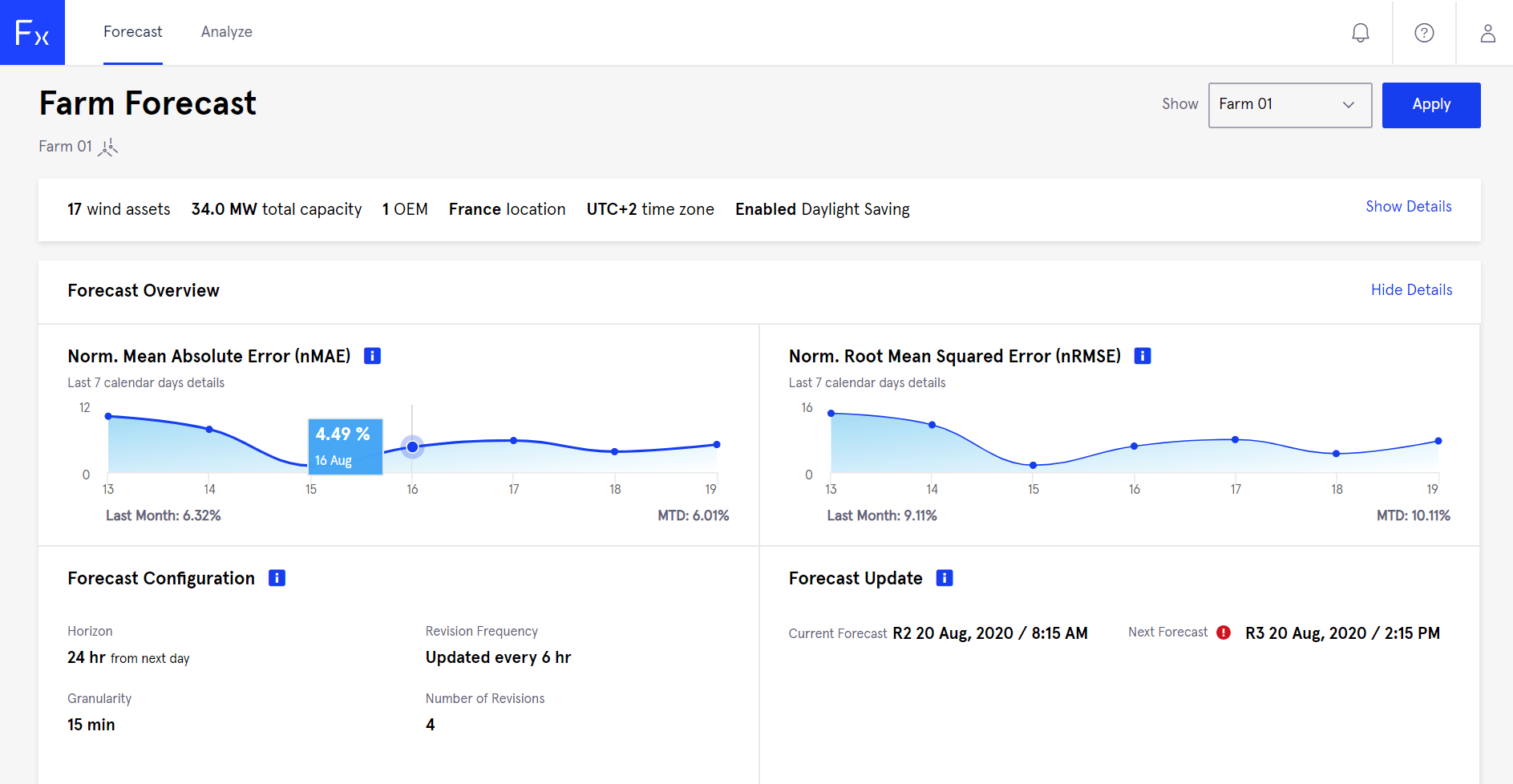

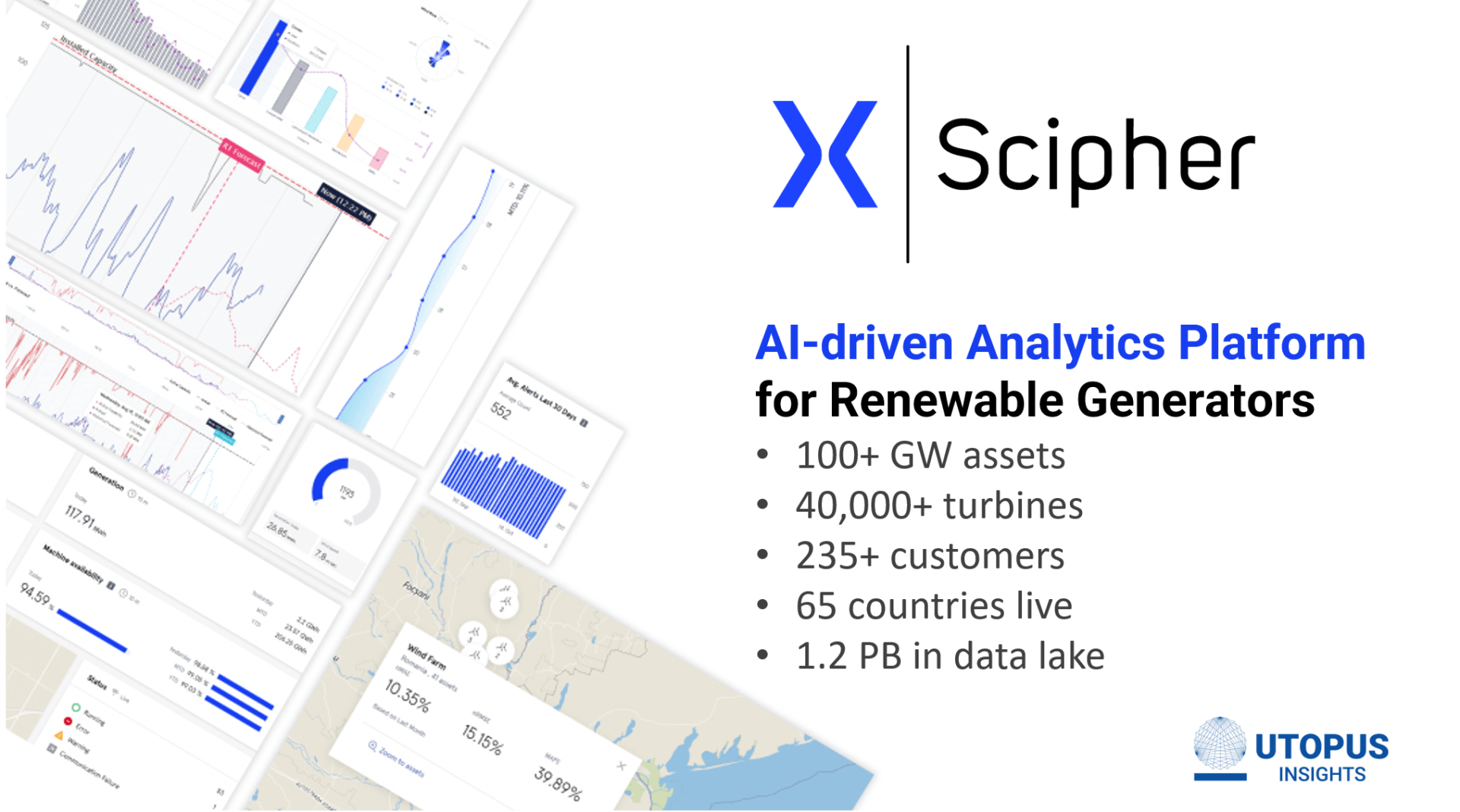

To ensure the highest quality input to track KPIs and loss analyses, Utopus Insights has developed proprietary data cleansing methods incorporating both data science and in-depth domain knowledge to filter noisy operational data. Hence the KPIs and production loss are calculated using only the most relevant, clean data, giving our customers highest confidence in our insights generated. Also, the filtered data are available in Scipher™ platform, along with various performance and downtime analytics tools, allowing your in-house analytics team to focus on the real production-impacting issues, not the data quality issues which typically consume 80% of data analysts’ time.

In addition to our high-confidence operational analyses, our

Scipher™ data platform manages 100+ GW of wind turbine assets alone. We can provide KPIs and production loss benchmarks at a portfolio, wind farm, OEM, turbine model, turbine age, as well as component level, and even by the specific type of loss level, such as unscheduled maintenance, degradation, icing, and noise curtailment. Our customers get a clear understanding of their turbine operations, and most importantly, can

pinpoint areas of improvement when compared with peers.

After customers identify areas of improvement for their wind farms, they can also get prescriptive corrective actions using the Scipher platform.

For example, partial performance is separated out from power curve analysis so that true performance problem causes such as blade contamination, pitch setting, etc. can be identified, while partial performance loss is calculated and accounted as turbine health problem and further breakdown to specific turbine components. After proper cleansing and categorizing of the data, we build a supervised learning model based on domain knowledge, and our advanced machine learning and AI algorithms identify potential production loss issues with high precision and recall.

It takes a combination of our unrivaled expertise in domain knowledge, vast data sources from a huge global fleet, and industry leading data science and analytics to cultivate actionable insights to maximize your wind farm production and reduce O&M cost.

News and Events